Revolutionizing Inventory Management: Former Tesla Supply Chain Experts Launch AI-Powered Solution, Atomic

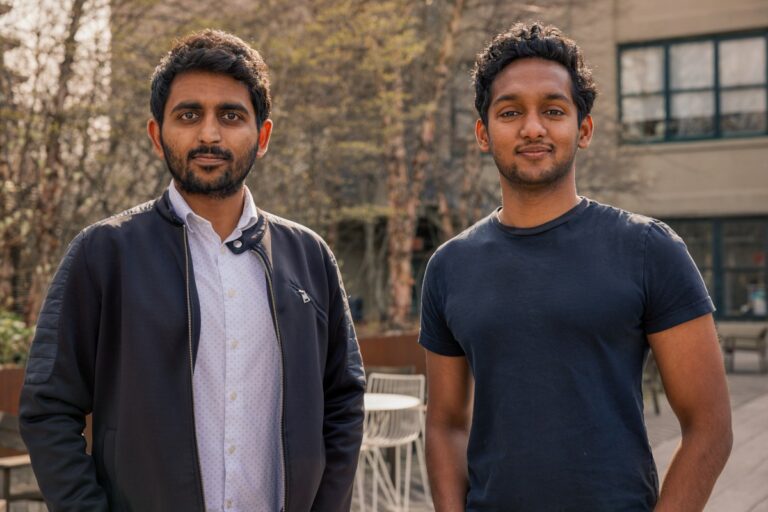

Tesla’s challenges in scaling production of the Model 3 sedan in 2018 led to the creation of a new startup, Atomic, which aims to revolutionize supply chain management using artificial intelligence (AI). Co-founded by former Tesla executives Michael Rossiter and Neal Suidan, Atomic is on a mission to streamline inventory planning and enhance operational efficiency for businesses across various industries.

Formation of Atomic: A Solution Born from Experience

Atomic was established within DVx Ventures, a firm led by former Tesla president Jon McNeill. With a successful seed funding round of $3 million backed by DVx Ventures and Seattle-based Madrona Ventures, Atomic is well-positioned to tackle the complexities of supply chain management.

Insights from Former Tesla Leaders

In an interview with TechCrunch, McNeill emphasized the firsthand experience Rossiter and Suidan had with supply chain struggles at Tesla. They witnessed the challenges leaders face, which drove them to create Atomic.

Revolutionizing Inventory Management with AI

Atomic’s innovative approach leverages agentic AI to facilitate quicker and easier inventory planning. The company has already partnered with pilot customers, achieving impressive results. For instance, one customer managed to reduce inventory levels by 50% while maintaining a remarkable 99% in-stock rate.

- Reduction of inventory costs by 20% to 50% for early customers.

- Enhanced working capital availability for businesses.

- Minimized risk associated with overstocking or stockouts.

The Need for Modern Solutions

In today’s volatile environment, demand for effective supply chain solutions like those offered by Atomic is on the rise. Suidan pointed out that traditional planning methods often involve tedious scenarios that consume valuable time and resources. Atomic’s software allows inventory planners to easily simulate multiple scenarios, making the planning process significantly more efficient.

Quick Implementation and Flexibility

Rossiter and Suidan pride themselves on the rapid implementation of Atomic’s solutions. Suidan explained, “You need a flexible data model that’s generalized, that can apply to everyone, allowing us to be up and running quickly.” The focus on precision control gives planners a sense of ownership over their plans, enabling them to navigate complex supply chain challenges effectively.

A Unique Approach to Supply Chain Transformation

Unlike many startups founded by former Tesla employees, Atomic embodies a philosophy developed during their time at the automaker. McNeill highlighted that Suidan and Rossiter built a comprehensive supply chain orchestration system from scratch at Tesla, transforming how the business operated.

- Implemented a unified planning system that eliminated silos between teams.

- Facilitated dynamic operational strategies that met business targets effectively.

As Suidan reflected on their work, he noted, “Our jobs became to build a system that could thrive and drive this company.” This transformation has influenced their vision for Atomic, which aims to deliver similar results to businesses everywhere.

Looking Ahead: Ambitions for Every Business

In 2023, Rossiter and Suidan aimed high once again, asking how their transformative approach could benefit all businesses that sell physical goods. “Our ambition is to support every company that sells physical goods,” Rossiter stated, showcasing Atomic’s commitment to innovation and excellence in supply chain management.

For more insights on supply chain advancements, you can check out related articles on our website or visit Forbes for industry trends.